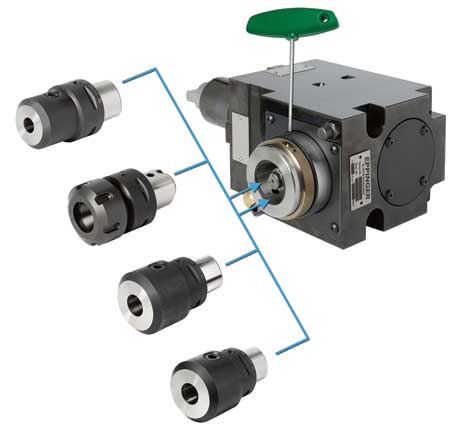

The EXSYS/EPPINGER CAPTO base holder is the smallest CAPTO interface.

"EXSYS Tool, Inc. recently introduced the EPPINGER CAPTO base holder, referring to it as the world's smallest CAPTO interface with the fastest tool changeover times for enhancing efficiency and productivity in CNC turning operations," said a company spokesperson.

"The compact size of the EXSYS/EPPINGER CAPTO base holder provides more space for machining larger workpieces as well as offers improved torque transmission and rigidity for increased tool accuracy. The interface's cone-style shape further adds to the solution's high precision and stiffness," said the spokesperson.

A special built-in release mechanism on the outer diameter of the EXSYS/EPPINGER CAPTO base holder's spindle provides optimal operator accessibility as well as makes it easy to lock and unlock the CAPTO adapters with a small Allen key. For quick tool changes, the CAPTO adapters are designed with automatic ejection.

Available for bolt-on and VDI-style turrets, the EPPINGER/EXSYS CAPTO base holder accommodates fixed and rotary tools, including the EXSYS/EPPINGER PRECI-FLEX system, and accepts all standard CAPTO/PSC adapters. The same CAPTO adapters used in milling applications will now work in turning operations.

According to Scott Leitch, a representative for EXSYS Tool, Inc., "With the product's superb rigidity, short tool changeover times and high accuracy, users will definitely experience enhanced productivity, profitability and an overall better machined component."

For more information contact:

Scott Leitch

EXSYS Tool, Inc.

11654 Corporate Lake Blvd.

San Antonio, FL 33576

800-397-9748

sleitch@exsys-tool.com

www.exsys-tool.com