SigmaBEND

SigmaMRP

SigmaNest

SigmaTUBE

SigmaTEK Systems, LLC, a provider of CAD/CAM nesting and manufacturing process automation, has released its latest product offerings.

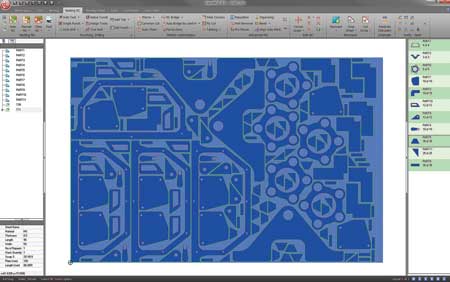

SigmaNEST Version 10, a CAD/CAM nesting program, is designed for laser, plasma, waterjet, oxyfuel, router, punch, press brake and tube/pipe cutting machines. Fabricators and manufacturers can view and try Version 10 at sigmanest.com. The site features hands-on interaction with the new Welcome Screen and short video overview.

According to the company, features of SigmaNEST V10 include:

- Enhanced material utilization: Upgrading to Version 10 can deliver up to $16,000 material savings per machine (based on average monthly material consumption of 100,000 lbs.).

- Faster and more accurate quoting: Program accounts for machine run time, adjusted cut speed (precision, high quality, positional cutting), material consumption and related manufacturing costs.

- Enhanced CAD import: Directly import files from leading CAD/CAM vendors. Assemblies are quickly imported and nested.

- Automation: Accelerate manually intensive tasks associated with work order management, costing and remnant tracking while bridging isolated systems and processes.

"SigmaNEST Version 10 expands beyond nesting to automate manufacturing processes and integrate business and manufacturing systems," said SigmaNEST Product Manager James Lindsey.

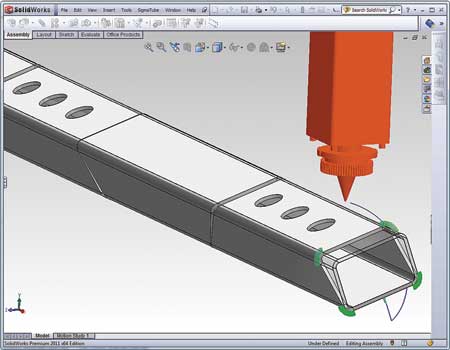

SigmaTUBE for Tube and Pipe Cutting

A complete tube and pipe cutting software, SigmaTUBE supports round, square, rectangular or triangular tube/pipe. In addition, structural material such as I-beams, H-beams, C-channel and angle iron are supported. Custom programs are available to fully maximize the advanced features of Mazak FabriGear, Trumpf, BLM, Bystronic, Amada and other 3D tube and pipe cutting laser machines.

Key features include:

- Flexibility allows multiple cutting machines to be driven with a single solution

- Supports multiple assembly model configurations

- Simple model refresh provides updated design revisions

- Cutting technology table sets cutting condition parameters

- Operates seamlessly within the SolidWorks environment.

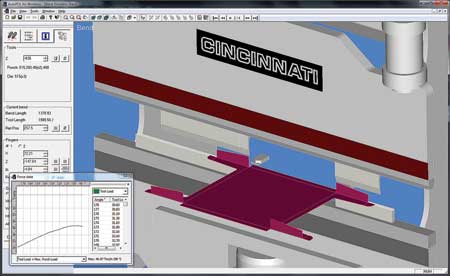

SigmaBEND: Automation and Flexibility

SigmaBEND is an off-line programming system for a variety of press brake machines complete with full 3D simulation of the bending process. SigmaBEND eliminates the need to run test parts while improving production speed, quality and flexibility.

"Automation, flexibility and control are keys to SigmaBEND," said Lindsey. "The software automatically recognizes bend information stored in 3D CAD files. SigmaBEND users have direct seamless access to SolidWorks and Inventor files while interfaces to NX, Pro/E, Catia, Solid Edge and CAD neutral file formats including IGES, STEP, SAT and Parasolid reduce file import, unfolding and nesting steps and errors. Other features include real-time 3D simulation with collision detections along with the ability for users to determine levels of manual control and automation for bend sequencing, tool and set-up selection, finger stop positioning and simulation."

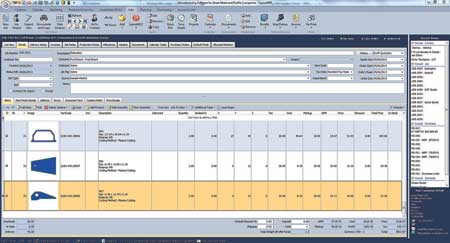

SigmaMRP: An MRP for Fabricators

Developed for the specific requirements of the fabrication industry, SigmaMRP is a manufacturing resource planning (MRP) system that manages transactions and communication with customers and suppliers, inventory of goods and raw materials, along with departmental and outsourced processes.

In addition to inventory, work order, process scheduling and progress tracking, fabricators who cut, bend or punch are faced with a need to catalog and recall remnants for future jobs. SigmaMRP is a scalable system with the ability to grow along with a manufacturer's evolving requirements.

SigmaMRP integrates with SolidWorks to import assemblies and manage native SolidWorks assemblies. SigmaMRP also links with SigmaNEST to create a totally automated software solution. Estimating and Quoting modules utilize the parts and nesting data in SigmaNEST to quickly produce formal time estimates and part pricing quotes.

For more information contact:

SigmaTEK Systems, LLC

1445 Kemper Meadow Drive

Cincinnati, OH 45240-1637

513-674-0005

sales@sigmanest.com

www.sigmanest.com

www.sigmamrp.com