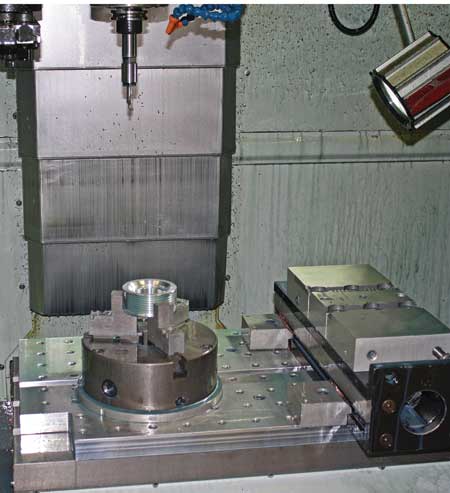

This accessory pulley is mounted in one of the VM10 mills to have its holes drilled and tapped.

The VMX64 is preparing to machine a large aluminum flange.

The Hurco control's intuitive user-interface simplifies programming and operation, which is especially important on multi-axis turning centers, such as the TMX8MYS that Waddle's Manufacturing uses.

The Hurco control's intuitive user-interface simplifies programming and operation, which is especially important on multi-axis turning centers, such as the TMX8MYS that Waddle's Manufacturing uses.

This part was machined from 7.5" diameter 6061-T6 aluminum bar by Waddle's Manufacturing & Machine. It is the case to a Big Block Chevrolet harmonic damper that is sold by Innovators West.

Waddle's operator is clearing a fixture of chips in preparation for another large flange.

Brad Waddle purchased Innovators West, Inc., a manufacturer of custom racing parts in Hutchinson, KS, in 1995 to combine his hobby with his career as a machine shop owner.

Shown are accessory drive pulleys and harmonic damper hubs. They have gone through the first operation and are ready for the second operation.

Brad Waddle purchased Innovators West, Inc., a manufacturer of custom racing parts in Hutchinson, KS, in 1995 to combine his hobby with his career as a machine shop owner.

The TM12 was the company's first Hurco lathe purchase. The lathe is used to turn everything from large aluminum castings to small steel and aluminum bar.

This part was machined from 7.5" diameter 6061-T6 aluminum bar by Waddle's Manufacturing & Machine. It is the case to a Big Block Chevrolet harmonic damper that is sold by Innovators West.

Innovators West makes high quality SFI 18.1 certified harmonic dampers for street and race vehicles. Dampers absorb and dampen the vibrations created by the engine from the firing pulses of the combustion process.

When the company's fleet of machines started to age, it had to find a replacement line of machinery that would provide the same or better quality of parts the shop was producing at a competitive price. "We interviewed several machine suppliers to get a feel for both the quality and selection of machines available, and also for their service after the sale," said Brad Waddle, Owner, Innovators West / Waddle's Manufacturing. "All machines break down over time, and how well machines are supported and serviced can make a big difference to a company's bottom line."

"After careful evaluation, we selected the Hurco TMX8MYS multi-axis mill turn (lathe with live tooling and Y-axis)," said Waddle. The TMX8MYS has X/Z/W/Y travels of 8.7"/22"/25.2"/4.4", maximum turning diameter of 13.2" with maximum bar capacity of 2.5" and turning length of 20.8".

Features of the TMX8MYS include:

- Enhanced graphics capabilities to represent sub-spindle operations

- Bi-directional part transfer

- Index position within one degree on main spindle, sub-spindle and live tool

- Live tool turret with Y-axis capability

- Faster servo turret instead of hydraulic

- Hydraulic system with heat exchanger that promotes thermal stability to increase reliability and extend machine life

- Ergonomic design features, such as front foot pedals to quickly open/close the chuck and engage/disengage the tailstock, for convenience and to promote productivity.

"With the TMX8MYS, production time has been reduced significantly due to the elimination of multiple setups," said Waddle. "Instead of three to four operations, these parts can be fully machined in one operation."

"In one operation we went from a 7.5 inch x 1.5 inch piece of 6061T6 aluminum bar," said Waddle. "This multi-axis machine with live tooling is able to perform the same processes that previously took three lathe operations and one mill operation - plus we are now able to engrave the numbers in the OD of the case. This new Hurco machine has allowed us to go from raw material to a finished part without the need for multiple machines and multiple operators. The operator can load the material, hit 'go,' and go back to running another machine. The machine runs nearly unattended for 8+ hours a day."

"The combination of a rigid machine with cutting edge technology and a knowledgeable representative led us to choose Hurco as the next line of machine tools. Hurco appeared to be on the cutting edge of software design, and also had solid well-built hardware," said Waddle. "We also got a great feeling dealing with Hurco distributor Gage Machine Tool. They took the extra time to answer all of our questions and reassure us that they were there for us should we need any help down the road. They have followed through with those promises along the way."

"As the machinists at Waddle's Manufacturing have learned, machining with the TMX8MYS mill turn machine means fewer setups and less material handling which equals greater productivity and profitability," said a company spokesperson. "While the specifications of the TMX8MYS are impressive, the control's intuitive user interface that simplifies programming and operation is what differentiates it from others in its class. For example, by simply checking a box, the control activates linear Y-axis motion. The sub-spindle functions are similarly straightforward. The control has multiple milling strategies to simplify programming, such as lines and arcs, circle, frame, slot, axial flats, and/or lettering."

The slot is an example of the control's flexibility and easy programming capabilities. The operator uses linear or rotary coordinates, including the Y-axis, by defining the slot width and then defining the start and end styles using a line or an arc. Additionally, the operator can choose different plunge feed types, including straight, zig-zag or rapid.

The part can be transferred with or without a cutoff operation. The two-stage process is designed to simplify part transfer and gives operators control over the process. In the Stage 1 screen, program the rapid and feed position: the chuck opens and closes automatically to transfer the part to the sub-spindle. In the Stage 2 screen, program the main chuck to open and define the position where the sub-spindle should rapid.

Waddle Manufacturing / Innovators West recently purchased an additional multi-axis mill turn lathe, the new TMX8MYSi. The company also has one VMX64 mill, one TM12 lathe (and another on order), two VM10 mills, Cincinnati equipment (Hawk 200 and Hawk 250), Falcon 300 lathes, Arrow 750 and 1000 mills, Sabre 2000 mills and two Maxim horizontals (650 HMC). In addition to the aftermarket high performance automotive parts it machines for the Innovators West product line, Waddle's Manufacturing machines parts for several local customers.

Brad Waddle opened Waddle's Manufacturing & Machine in 1984 in Salina, KS. His business stayed busy machining parts for numerous industrial companies in the area, but he decided to combine his hobby with work in 1995 when he purchased Innovators West, Inc., a manufacturer of custom racing parts in Hutchinson, KS. Since that time, both Waddle's Manufacturing and Innovators West have experienced steady growth, both in machining parts for external customers and machining its own product line of parts. Innovators West also provides specialty services, such as custom designed dampers for special applications, ring gear lightning and REM polishing.

For more information contact:

Innovators West

Waddle's Manufacturing

Salina, KS 67401

785-825-6166

www.innovatorswest.com

Hurco Companies, Inc.

One Technology Way

P.O. Box 68180

Indianapolis, IN 46268

800-634-2416

317-298-2622

info@hurco.com

www.hurco.com

MW ONLY

KS, N.W. MO, NE

Dirk Gage

Gage Machine Tool

10668 Widmer Rd.

Lenexa, KS 66215

913-894-1233

dgage@gagemachinetool.com

www.gagemachinetool.com