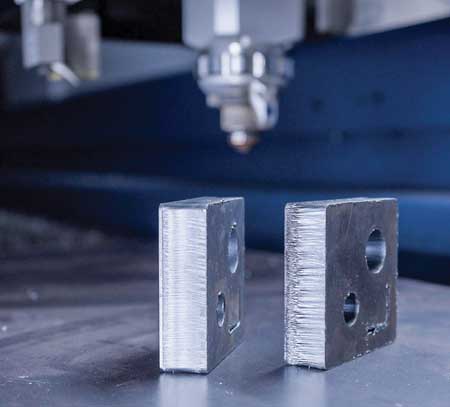

With the Cutting Assistant, users get the best possible laser cutting parameters for their material. All they need to do is take a photo of the cut edge using a hand scanner. AI takes care of the rest.

"After about five runs, the solution enables perfectly cut component edges-with no experience or programming required," said a TRUMPF spokesperson.

TRUMPF has introduced a Cutting Assistant application, which employs artificial intelligence to help users improve the quality of laser-cut edges. Production employees just take a picture of their component's cut edge with a hand scanner. Then, the solution assesses the edge quality, evaluating it using objective criteria such as burr formation. With this information, the Cutting Assistant's optimization algorithm suggests improved parameters for the cutting process. Then the machine cuts the sheet metal once more. If the part quality still does not meet expectations, the user has the option to repeat the process. This solution is available for all TruLaser series laser cutting machines purchased as of May 2025, which feature a power output of 6 kW or higher.

"When laser cutting, fabricators can find it challenging to determine the correct parameters to use for their material grades," said a company spokesperson. "Materials that are not optimized for laser cutting often produce edges with wide variations in cut quality, forcing production employees to constantly change the technology parameters. This involves adjusting each individual parameter one by one-a process which demands a lot of time and employee experience. This presents a challenge for many companies, especially those with inexperienced workers in production positions. By integrating the Cutting Assistant into the machine software, optimized parameters can be transferred seamlessly into the software without the need for programming. This saves time and reduces errors."

In the future, data from applications in the field will also be incorporated into the solution. This will enable faster and more reliable results, because the self-learning system will continuously improve.

TRUMPF regularly provides users with online updates that they can download to their machines for maximum productivity and quality.

For more information contact:

TRUMPF Inc.

Farmington Industrial Park

Farmington, CT 06032

860-255-6000

info@us.trumpf.com

www.us.trumpf.com