The CrazyDrill SST-Inox is designed for stainless alloys.

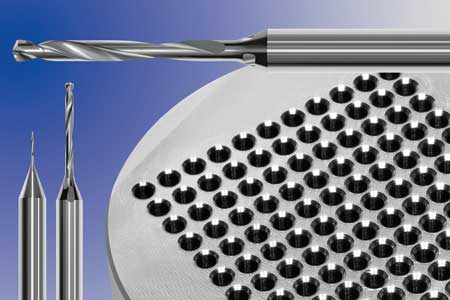

Two versions of the CrazyDrill SST-Inox are available: one for machining with external cooling, another with integrated cooling through the shank.

CrazyDrill SST-Inox offers diameters from 0.3 mm (.0118") to 2 mm (.787") for drilling depths up to 8 x d.

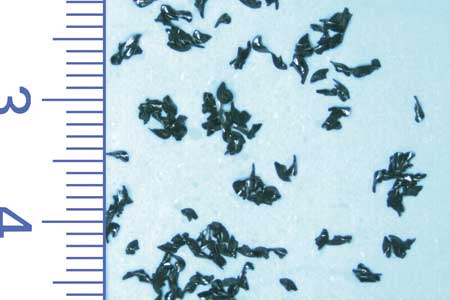

CrazyDrill SST-Inox generates short chips, an important factor for long tool life and high process reliability.

Mikron Tool SA Agno has developed CrazyDrill SST-Inox, a small drill especially adapted for stainless and acid-resistant steels. According to the company, the drill is comprised of solid carbide and features enhanced flexibility and thermal shock resistance as well as high breakage ductility.

The geometry has also been revised and adapted to meet the needed requirements. "The reduced transverse cutting edge reduces the feed force, provides good self-centering of the drill and generates short chips, even with long-chip-production materials," said a company spokesperson. "Cutting edge breakages are thus avoided. The result for the customer is a better tool life, more process reliability and better productivity.

"A difference to standard tools consists in the drill top profile: the slightly reduced drill diameter after the short top section reduces the friction and therefore the heat development, reducing the torque. This benefits process reliability as well as surface quality. The digressive flute, divided into two areas, provides good chip removal. A chip breakage area with a 32° flute facilitates the chip breakup, and the chip removal area with a 12° flute allows quicker chip removal.

"The new coating resists thermal load, and due to a smooth surface the friction is limited and allows for good chip removal. The adhesion to other materials is low, avoiding chip cementing at the cutting edges (no material build up at cutting edges).

"The new drill CrazyDrill SST-Inox, compared to standard drills, offers 1.5 to 2 times higher cutting speeds and feedrates and steps up to 1 x d."

Mikron Tool has developed a version of the drill with integrated cooling. In this version, three to four cooling channels pass through the shaft and exit at the conical neck. "This provides an efficient cooling jet on the top of the drill for controlled heat and continuous chip removal," said the spokesperson. "The advantages, when compared to drills of the same product family but without through cooling, include better tool life expectancy, increased steps from 1 to 2 x d, and increased cutting speed and feed from 20 to 30%."

CrazyDrill SST-Inox drills are available from inventory from 0.3 to 2 mm (.0118" to .0787") with increments of 0.05 mm (.00197") and a usable length of 8 x d. Special dimensions are available on request.

For more information contact:

Mikron Corp. Monroe

200 Main Street

P.O. Box 268

Monroe, CT 06468

203-261-3100

mmo@mikron.com

www.mikron.com/tool

IMTS 2014 Booth S-9295