ZOLLER »3dCheck«

Broad spectrum of applications with simple operation throughout

Three-dimensional digitalization of tools and workpieces

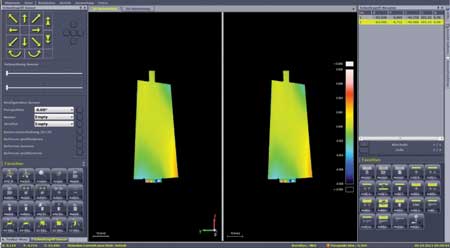

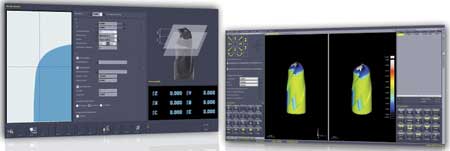

Combined 2D and 3D measurement and target-actual comparison of a turbine blade and milling cutter

According to Zoller, 3D is the trend in measuring technology. "A number of geometries can only be captured and evaluated in 3D, and they are also a lot closer to the construction drawings that are prepared in 3D," said a company spokesperson. "ZOLLER has adopted this trend and presents visionary options in metrology with the 5-axis CNC machine »3dCheck«.

"ZOLLER enables the fully automatic measurement and evaluation process for all current standard geometries of round tools. ZOLLER has also simplified the approach for the user, in comparison to other systems available on the market.

"The digitalization of workpieces is effortless due to the calibrated linkage between the transmitted light image processing and the 3D sensor of the measuring machine."

Aligning the workpieces and determining the significant geometric characteristics is performed automatically, as well as the positioning of the transmitted light image processing to the 3D sensor. In the next step, 3D digitalization of the workpiece surface is performed via a measuring plan, which was filed once for the tool via the graphic ZOLLER »pilot« interface. The 3D measurement data set is evaluated automatically after digitalization.

The compact design of the ZOLLER »3dCheck« was developed specifically for the 3D digitalization application field. "The universal machine mechanics offer a broad spectrum of applications and help ensure optimal positioning of the measuring sensor in relation to the surface of the workpiece. The universal toolholding fixture provides the user with high precision clamping of the workpieces. The highly detailed display of the workpiece geometry is enabled by the high lateral resolution of the sensor."

In conjunction with a specially developed calibration process, the solid machine design allows complete digitalization of workpieces from different sensor perspectives. "These are fed back automatically into a uniform workpiece coordinate system without requiring the elaborate use of reference measuring points or the mechanical mounting of backdrops," said the spokesperson. "This results in considerable time savings when preparing workpieces for measuring."

Feeding the various measuring perspectives and positions into a uniform workpiece coordinate system is performed automatically. A topographic target/actual comparison and optional cross sections allow a complete analysis of the workpieces at a glance.

According to the company, the analysis of the 3D measurement data is another major advantage compared with existing measurement methods. They can be exported in a standardized format and can be processed further in CAD or in 3D analysis applications.

Fully automated and customized measuring and analysis programs can be developed for 3D digitalization and the analysis of workpieces and tools based on the existing 3D basic software.

For more information contact:

Zoller Inc.

3753 Plaza Drive

Ann Arbor, MI 48108

734-332-4851

sales@zoller-usa.com

www.zoller-usa.com