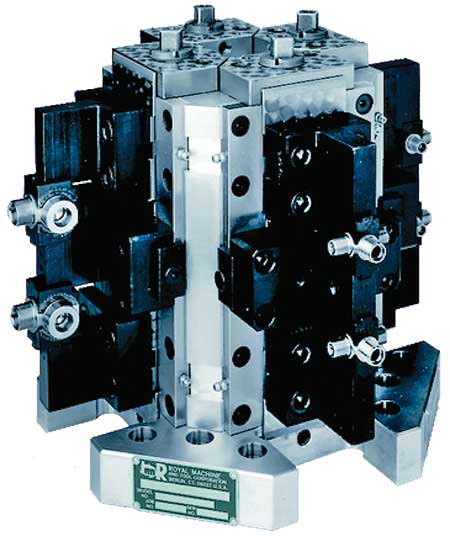

QVC 500 Quad Vertical Chucking Fixture with American Standard Tongue & Groove Master Jaws with a patented Cartridge Assembly.

Royal Machine QVC can hold up to eight parts on horizontal machining centers permitting continuous spindle use with less downtime for part change-over.

When the word chuck comes to mind, the first associated thought is a lathe.

However, today many machining centers are being tooled with common chucks. For the most part, this is much more economical than building a special fixture, either manual or hydraulic, that may only be useful for one particular part.

The simplest concept is a base plate with a manual chuck with step jaws mounted to the plate. It is not a new concept, but one that has been expanded and improved over the years to improve change-over, quality and production.

This allows the fixture to accommodate a number of parts in various diameters by gripping on the inside or outside diameter. The convenience may be that what is gripped on the lathe can be gripped in the machining center. Thus, keeping the inventory of fixtures at a minimum, and also providing quick, simple change-over and set-up.

During the past twenty years the manufacturing sector has changed considerably with high volume jobs having moved overseas where labor rates are much less. Today, U.S. manufacturers have to be creative and be able to develop quick change-over from job to job, provide shorter runs, reduce set up time and improve quality. With this in mind, development has taken place among chuck manufacturers to provide a variety of chuck options for machining centers.

Two Options to Consider

One option is a four-sided vertical chucking tombstone in place of a manual chuck on a base plate. For example, Royal Machine and Tool's QVC Quad Vertical Chucking fixture, which provides master jaws as American Standard tongue & groove and allows readily available jaws to be applied. Each side can also be in a self-centering mode or in a compensating mode permitting the fixture to grip two parts per side. There are also a number of commodity type models available which may be suitable for less aggressive machining.

This style fixture can allow two parts per side or eight parts total to be clamped on a single fixture, providing access to three surfaces for machining in a single operation. It is most suitable but not limited to machining tees, crosses and elbows for the plumbing industry as well as valve bodies for the flow control industry.

Another option is that manufacturers have recently introduced hydraulic actuation to their fixture designs which, in turn, provide quicker and more consistent gripping forces. The high cost of hydraulic chucking fixtures can be justified in many cases because the fixtures multiple chucks on each surface provide extreme repeatability in changing out chucks to accommodate different parts.

Hydraulic actuation fixture designs are not a new concept. Original vertical chuck fixtures by Royal Machine have remained active in the flow control and valve manufacturing industry for over 30 years while still maintaining tolerance requirements.

"Today's ever increasing demands for greater cost efficiencies in manufacturing provide sound reasoning for evaluating and considering the many benefits/features of QVC's," said Bernie McAloon, Sales Manager, Royal Machine & Tool Corp.

Authored by Bernie McAloon, Sales Manager, Royal Machine & Tool.

For more information contact:

Bernie McAloon, Sales Manager

Royal Machine & Tool Corp.

P.O. Box Y

4 Willow Brook Drive

Berlin, CT 06037

860-828-6555

royal@royalworkholding.com

www.royalworkholding.com