A robotic spray system applies coating to a rotor while it spins on a Chain-On-Edge spindle, allowing full 360° coverage with minimal overspray.

An operator prepares a spray gun for automatic coating on a Chain-On-Edge conveyor system just before starting a high-precision production run.

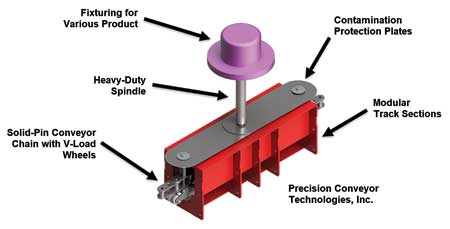

Labeled diagram of a Chain-On-Edge conveyor with rotating spindle and enclosed track

An example of a Chain-On-Edge system.

Examples of parts processed using COE conveyors.

Chain-On-Edge (COE) conveyors are a specialized but essential tool in modern finishing and manufacturing environments. Though they rarely get the spotlight, these systems quietly handle some of the most critical applications in paint, powder and UV coating lines-especially where part rotation, process repeatability and consistent coating quality are nonnegotiable.

The Basics

At its core, a COE conveyor consists of a continuously driven chain with evenly spaced vertical spindles. Each spindle supports a fixture that adapts the spindle to a specific part design, ensuring a secure and repeatable interface.

Spindles can be:

- Rotating, to allow full 360° coverage during coating or curing

- Fixed, for processes that require a locked orientation

- Detented, where parts rotate and lock into indexed positions for multi-angle processing.

Some advanced designs include an enclosed track with bearing load wheels and upper and lower stabilizing bearings, providing smooth, wobble-free movement even under heavy or tall parts. Chain pitch, spindle size and load capacity are all tailored to match part geometry and production requirements.

Why Use COE?

COE systems shine where coating tolerances are tight, layouts are compact and repeatable part handling is required. When properly engineered, they precisely index, spin and move parts through multiple process zones-making them suited for high-performance production environments.

That said, not all COE systems are created equal. Stability, rotational accuracy and layout efficiency vary significantly depending on mechanical design. Just as important is real-world reliability-some systems struggle in harsh manufacturing environments where heat or chemical exposure are common.

For processes that demand precision, uptime and space-conscious integration, it is essential to choose a platform engineered not just to function-but to last.

Common parts processed on COE:

- Aerospace fasteners, shims and bushings

- Automotive wheel components, hubs, mounts, rotors and brake parts

- Sporting goods including helmets and baseball bats

- Cookware, mugs, glassware and cast iron

- Rubber-to-metal bonded parts

- EV components and battery parts

- Military components, mortars, projectiles and shells

- Oil field pipe couplings, nuts and fasteners

- Plastics including bottles, caps and automotive parts.

A Closer Look at Performance

One of the key advantages of COE systems is their repeatability. A well-built line can reliably deliver hundreds of thousands-or even millions-of coated parts with minimal operator involvement. The ability to spin parts during processing enables optimized coating coverage with fewer spray guns and less overspray, saving time and material.

COE systems also open the door to significant labor reduction through automation. From automatic loading and unloading to integrated inspection, smart fixture tracking and real-time diagnostics, these systems minimize the need for manual intervention-freeing up operators for higher-value tasks and helping facilities scale production without scaling headcount.

Despite these benefits, COE conveyors are still underutilized in many industries. When applied correctly, they offer a robust and efficient way to coat, cure and handle parts at scale.

Applications Across Finishing & Automation

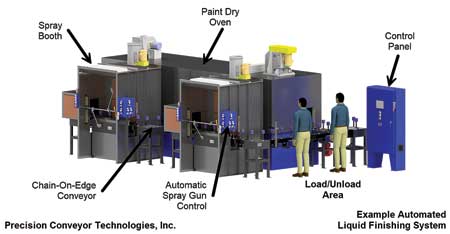

COE conveyors are used across a wide range of finishing processes and automation tasks. Their versatility and ability to integrate with modern controls make them the backbone of many automated systems:

- Liquid painting-Supports robotic or manual spray application with consistent indexing and smooth part rotation for precise film builds.

- Powder coating-Enables uniform coverage with fewer guns by rotating parts during electrostatic spray. Often combined with masking, pre-treatment and automated touch-up.

- Conveyorized curing-Suited for IR, convection or UV curing processes. Stable motion and spindle control help ensure even heat exposure and uniform finish quality.

- Other automation processes-Integrates with loading/unloading systems, weight checks, barcoding and fixture changeovers. Compatible with PLCs, servo motion and smart sensors for closed-loop control.

Engineering for Reliability

Designing a reliable COE system goes beyond simply linking spindles to chain. Factors like part weight, rotational inertia, high-temperature exposure and cleaning access must be considered up front. Bearing selection, spindle alignment and fixture interface design all play a role in ensuring long-term performance.

And while the base concept has been around for decades, today's COE platforms benefit from modern advancements: servo-driven indexing, sensor feedback, predictive maintenance and modular control integration-allowing them to perform smarter and last longer.

Authored by Jeff Smeker, VP of Engineering, Precision Conveyor Technologies Inc.

For more information contact:

Precision Conveyor Technologies Inc.

3785 Lane Road

Perry, OH 44081

440-352-6100

info@precisionconveyor.com

www.precisionconveyor.com