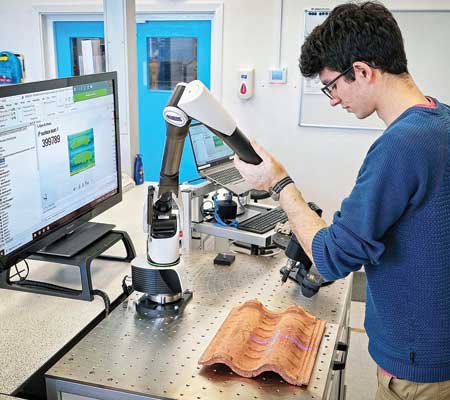

Luke Kelly uses the LK FREEDOM Arm and Nikon laser line scanner to inspect a concrete roof tile in the metrology room at the BMI Technical Center, Crawley.

A tool steel round nose knife from a tile production machine being laser scanned.

One purpose of the end-of-arm touch probe is to identify the position of dimples in the LK FREEDOM Index Table so that after it has been rotated to provide easy all-round access to the part being inspected, the coordinate system in the PolyWorks software can be updated quickly using an LK macro.

Concrete roof tiles on a production line at BMI Group's Shawell manufacturing facility in Lutterworth, UK.

Few people outside the tile-making and building industry know that a good quality roof tile has to be manufactured to a tolerance as tight as plus or minus half a millimeter. It places a requirement on the research and development and quality control (QC) functions in that sector to measure prototype tiles and mass-produced tile samples to ensure they are accurate. Metrology staff also need to check the wear on molds used to make the product, as well as the condition of tungsten carbide wear parts and steel tooling in the production machinery. Sometimes it is necessary to reverse-engineer replacement components for older machines to avoid delays in production, or to produce a CAD model to update a legacy tile, or inspect a 3D-printed item to assist a design process.

This is the scenario at the Crawley Technical Center of BMI Group, a manufacturer of flat and pitched roofing systems, where since July 2024 Design Engineer Luke Kelly and several of the team have been using a portable measuring arm inspection solution supplied by LK Metrology.

Superseding a smaller and now unsupported arm and touch probe, which were used alongside conventional, manually-intensive metrology equipment like calipers and height gauges, the new inspection area comprises a 7-axis, multisensor FREEDOM Arm Classic Scan with a 2.73 m reach equipped with a touch probe and an H120 laser line scanner, which since the end of 2023 has been manufactured by LK following its acquisition of Nikon Metrology's laser scanner hardware and software business. Together with a rotatable, 300 mm diameter FREEDOM Index Table, the lightweight carbon fiber arm is mounted on a metrology table, all elements supplied by LK. Additionally, Innovmetric's PolyWorks Inspector software was purchased from reseller 3D Scanners (UK) to provide advanced point cloud analysis, evaluate surfaces, measure geometrical features, generate colored heat maps for part-to-CAD or scan-to-scan comparisons, and generate full reports.

One of the most important inspections performed is on the die-cast aluminum molds used to form the underside of concrete tiles in the extrusion process. The pallets are subject to abrasion and erosion, and there are tens of thousands of them in a set, according to the size of the tile manufacturing operation. Re-equipping a large factory with these pallets can cost well in excess of $1 million, so it is important to take samples regularly to assess their condition, predict lifespan, and identify production line issues. This process is now significantly streamlined with the new LK system, which is especially useful as the frequency with which pallets are sent to the Technical Center for analysis has increased in recent years. The scale of the task is amplified by there being hundreds of pallet sets across the group, including for main tiles, cloak verges, ridges, and special fittings.

Kelly explained, "Our previous metrology methods for assessing the aluminium pallets, and indeed the tiles themselves, were time consuming to set up and analyse. We took only 16 measurement points around the edges of each pallet, for example, so they would not show some of the wear in the center of the objects that the laser scanner is capable of.

"The amount and quality of the metrology data has increased enormously with laser scanning, allowing us to provide much more detailed reports to our tile factories so they can make any necessary adjustments to the production line and predict the number of passes the pallets can make before needing replacement.

"Reverse engineering of tiles using the scanner is much faster and richer in detail than our previous method of taking individual cross sections. For some applications where we want a reference CAD model, it will save us days of work creating it from scratch, as we can simply use the STL output from the laser scanning software.

"The touch probe is mainly needed on the end of the LK arm for checking adherence to the design and to EN 1024 standards. Inspecting the requisite 10 clay tiles each time would take too long to complete by laser scanning."

The range of component sizes in Crawley is vast, from 0.5 mm thick sheet metal through small plastic and metal clips to a solar roof panel measuring more than 1 m across. The LK metrology solution copes with all of them and enables much more comprehensive reporting than previously needed. Kelly said that scan times are quick, and the reporting tools are easy to use, rapidly producing easy-to-understand images for further analysis by specialists. The index table is useful for accelerating the measurement of some smaller parts where all-round access is required. It is another reason for having the end-of-arm probe, which is touched into three or more fiducial dimples machined into the top of the table and around its periphery. It is then a simple matter to click the on-screen FREEDOM Index Table macro in the PolyWorks software to update the coordinate system and continue capturing the surface data.

The BMI Technical Center is now considering the acquisition of an LK metrology-grade tripod so that the portable measuring arm can be taken into the group's factories to carry out QC in-situ. It would reduce the time delay and costs associated with having sample pallets, tiles, and other items such as legacy machinery components delivered to Crawley for inspection.

For more information contact:

LK Metrology, Inc.

29550 W.K. Smith Drive, Unit B

New Hudson, MI 48165

810-263-6100

www.lkmetrology.com