Caracol has opened its new headquarters in Austin, TX, more than tripling its space for systems production and application development, with capacity to produce up to AM platforms annually.

The new headquarters is built to bring advanced manufacturing closer to U.S. customers, allowing Caracol to accelerate innovation and deliver solutions tailored to the North American market.

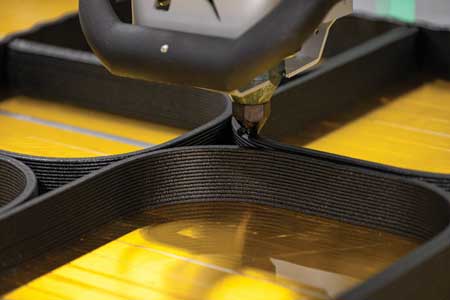

Caracol, a provider of large-format additive manufacturing (LFAM), announced the opening of its new 10,000 sq. ft U.S. headquarters and production center in Austin, TX, more than tripling its space for systems production and application development. This expansion strengthens Caracol's long-term commitment to North America's manufacturing industry, enabling faster delivery, tailored solutions, and deeper collaboration with local customers. With a local supply chain, shorter lead times, direct technical support and co-development opportunities, Caracol is positioned to be the go-to partner for advanced manufacturing solutions in the United States, the company reported.

"This new facility will allow us to accelerate innovation and deliver solutions tailored specifically for the North American market, where demand is growing rapidly," said Francesco De Stefano, CEO of Caracol. "When we opened our first Austin office in 2023, it was about establishing a presence-now it is about building capability. This expansion means faster progress, closer collaboration with our customers, and solutions designed for their unique challenges-not to mention supporting domestic production in the U.S. As one of Europe's fastest-growing deep tech companies, we are excited to bring that same momentum to North America."

The new headquarters is built to bring advanced manufacturing closer to customers. Following 224% growth in systems delivered in the past 12 months, the facility combines R&D, application development, and large-scale production under one roof. Alongside dedicated assembly, testing and delivery areas for Caracol's proprietary Heron AM and Vipra AM robotic platforms, it also features an application hub for developing specialist projects with local manufacturing companies, providing them direct access to Caracol's engineering expertise, materials, and products testing. This hub is designed to accelerate co-development, allowing partners to validate new applications, optimize manufacturing processes, and scale innovative solutions directly with Caracol's team.

With capacity to produce up to 100 Heron AM and Vipra AM platforms annually, the site is built to the same ISO 9001, EN 9100, and ISO 14001 standards as Company's European sites, enabling aerospace-grade quality, environmental responsibility, and cost-efficient production, all while cutting emissions and costs tied to overseas shipping.

For more information contact:

Caracol

1007 South Heatherwilde Blvd.

Suite 700

Pflugerville, TX 78660

info@caracol-am.com

www.caracol-am.com