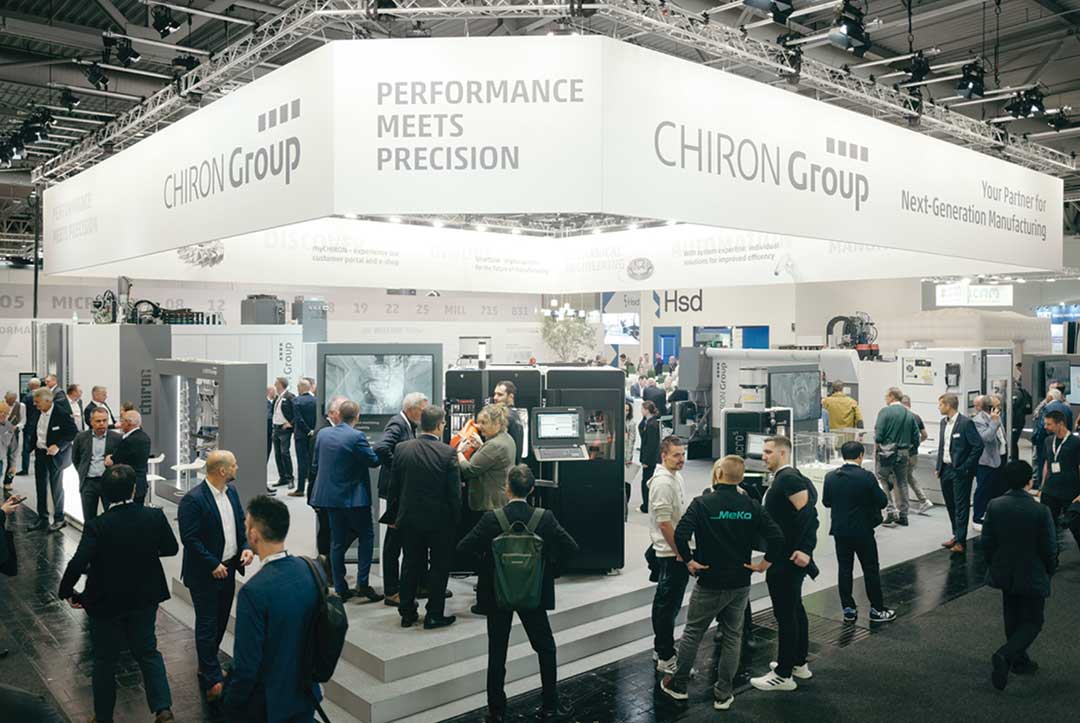

The CHIRON Group presented its entire range of modern, efficient production solutions for all target industries.

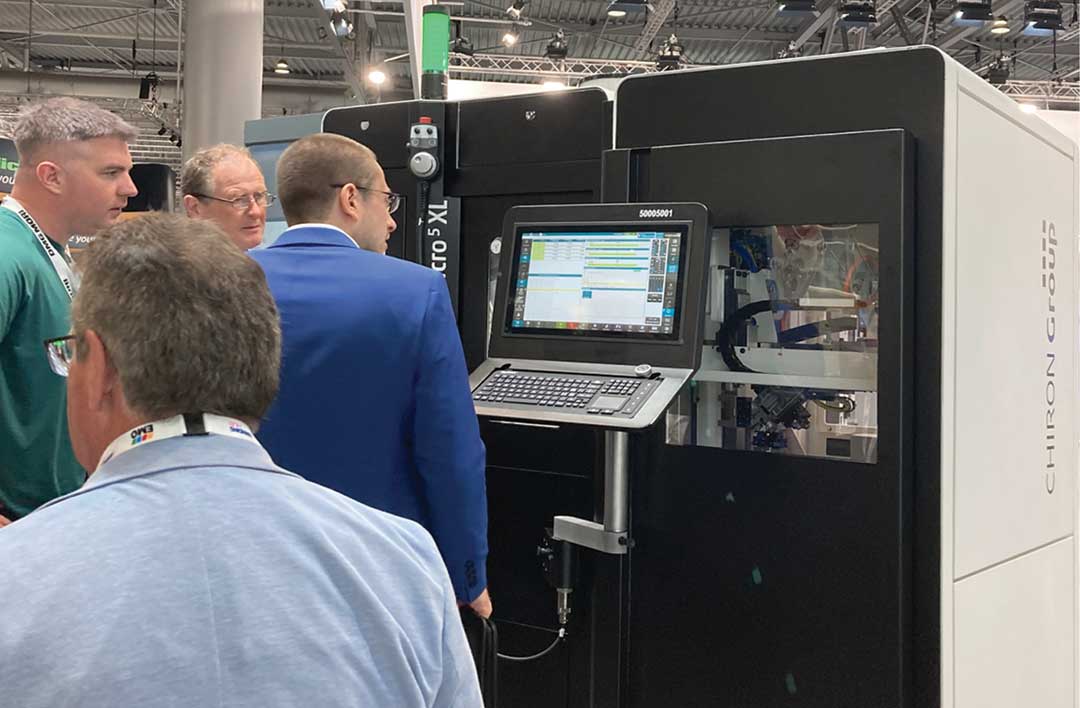

The new Micro5 XL and the Variocell PICK&PLACE automation system offer an integrated combination for extended possibilities in micromachining.

Precision machining of a bone watch-an example of the extended range of applications with the Micro5 XL in medical and precision technology.

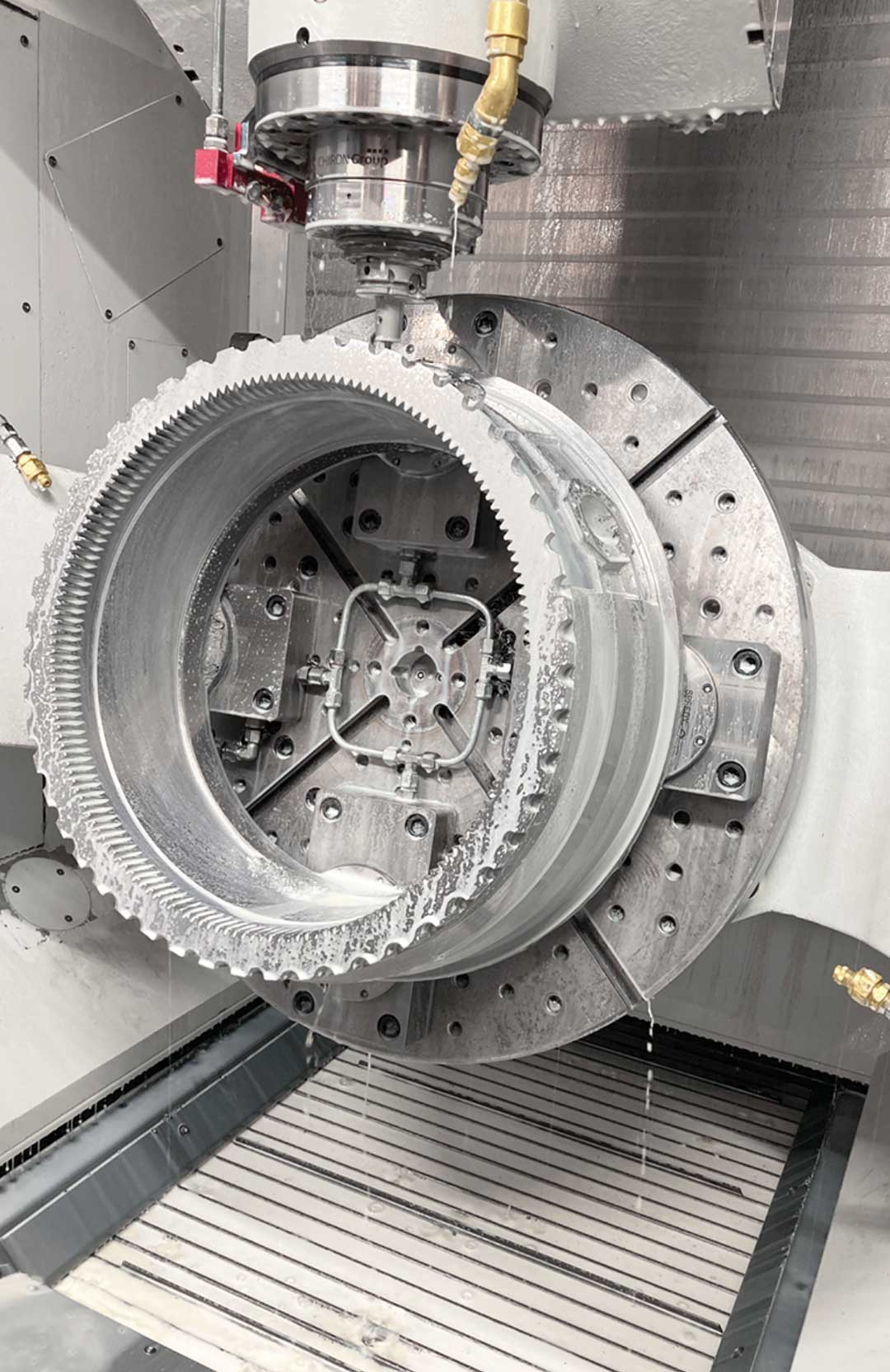

The FZ 19 S 5-axis with open work area and view of the turbine housing completely machined in a continuous process.

Attendees were able to follow five processes live on the FZ 19 S 5-axis during the machining of a turbine housing: rough machining, turning, skiving, drilling, and simultaneous 5-axis milling.`

Four hours of autonomous production of pump housings on one side of the table, two hours machining fan covers for mechanical engineering with the productive combination of DZ 15 W and Variocell UNO.

The CHIRON Group demonstrated at EMO its latest solutions to meet the requirements of modern production in applications such as micromachining for medical technology, watches and jewelry, electrical industry to the complete machining of complex turbine components for aerospace, and highly productive automotive and mechanical engineering applications.

Micro5 XL with Automation

The Micro5 XL, which celebrated its official premiere at EMO 2025, offers more travel distance, increased cutting performance, and maximum flexibility in micromachining. The Micro5 XL machines workpiece cubatures of up to 120 mm on a footprint of just 1.7 sq. m with dynamic BC 5-axis kinematics, spindle speeds of 40,000 RPM or 50,000 RPM, and jerk values of up to 900 m/s3.

The Micro5 XL demonstrated its strengths in 5-axis simultaneous HSC machining on the "bone watch" demonstration part-a base with a watch case and bracelet in the style of several bone plates arranged in a row-where it maintained excellent surface quality and reproducible precision.

The new Variocell PICK&PLACE automation variant was responsible for feeding the raw parts into the clamping device and placing the finished bone watches in the storage unit. The productive combination is supplied as a unit and can be put into operation immediately as a plug & play solution. The pallet trolley offers space for up to 12 pallets measuring 400 mm x 300 mm and a height of up to 50 mm in a compact footprint. A key advantage: the operating logic is identical to the Micro5 XL. It is operated from the front with the best view of the milling process, and several production units can be positioned in close succession-production can simply grow with the quantities.

Micro5 Model

The Micro5 micro machine is the basis for the new XL version. Weighing just 550 kg and with a 230 V connection, it can be flexibly integrated into almost any production environment. Despite its compact footprint, it offers high static and mechanical rigidity and delivers the required precision for the most demanding geometries, the company reported. In live operation at EMO 2025, the Micro5 produced the fine connectors for aerospace.

DZ 15 W with Variocell UNO

With the DZ 15 W, the CHIRON Group presented a twin-spindle machining center that combines productivity, flexibility, and autonomy in a compact space. The in-house developed rotary table with direct drive positions 360° in less than a second-wear-free, precise, without backlash, according to the company. Two processes were on display on both sides of the table: the production of aluminum pump housings for the automotive industry and the manufacture of cast iron fan covers for mechanical engineering.

Due to the double spindle and automation with a Variocell UNO, the machining process continues on one side while loading and unloading takes place in parallel. The result: processes parallel to machining time, continuous parts supply and optimum use in shift operation.

The automation unit with workpiece storage and changing device enables short cycle times and high autonomy and extends the application possibilities of the DZ 15 W beyond large series.

Five Processes, One Continuous Process with the FZ 19 S

Whether used in aerospace, energy, or mechanical engineering, the FZ 19 S 5-axis is designed for high-speed cutting of high-strength materials in demanding applications. In live operation, visitors were able to follow all the production steps of a turbine housing: rough machining of the raw part, turning of contours and diameters, skiving for precise gear cutting, drilling of fits in high-strength material, as well as simultaneous 5-axis milling of free-form surfaces and complex, high-precision geometries.

The gantry moving portal design enables high static and dynamic rigidity, while the active cooling of all components offers stable temperature management-providing process stability even with long machining times.

Added Value for Sustainably Productive Processes

In addition to the live demonstrations, the CHIRON Group presented its complete range of services. In the interactive showroom, the broad technology portfolio and the machine pool with reconditioned used and available existing machines were presented-a quick and cost-efficient way to modernize production.

The experts at the booth also provided advice on key competencies that make manufacturing solutions even more efficient and sustainable: the SmartLine digital systems for greater efficiency, availability, and productivity. The Services division provided information on the comprehensive portfolio with services such as spindle repair, overhaul and optimization, coordinated service agreements, the myCHIRON customer portal with e-shop for spare parts and refurbishment solutions for a productive second machine life for proven machining centers.

Matthias Rapp, Vice President Global Marketing, said: "Our innovations such as the Micro5 XL with Automation Variocell PICK&PLACE met with enormous interest and the feedback was consistently positive. The discussions confirmed this: automation and sustainable production remain key topics in the industry-and we are addressing them convincingly."

For more information contact:

CHIRON America, Inc.

10950 Withers Cove Park Drive

Charlotte, NC 28278

704-587-9526

info.america@chiron-group.com

www.chiron-group.com