TMAC learns the optimum power for each tool and continuously maintains a constant tool load by automatically adjusting the feedrate in real time. The result? Decreased cycle time, longer cutter life, and more machine uptime, especially with difficult to machine materials.

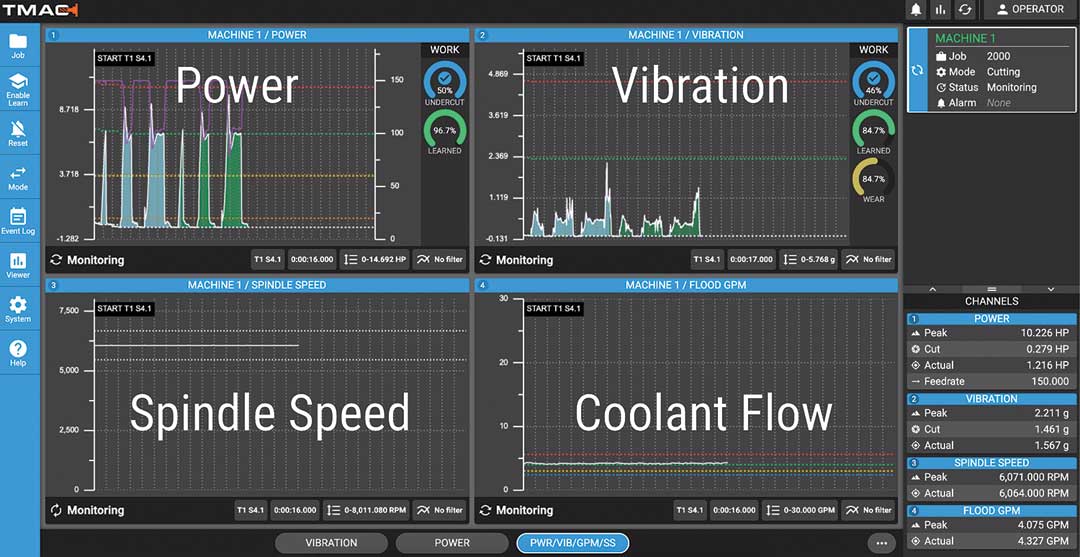

TMAC monitors multiple processes and sensor channels simultaneously.

The HMI visually displays each cut and the wear status of every tool in real time, empowering users with immediate control over their cutting processes.

A Caron Engineering customer recently adopted Caron Engineering's Tool Monitoring Adaptive Control (TMAC) system, which improved its lights-out operations in a variety of ways.

The customer was operating a fully automated, lights-out machining cell using a CNC turning lathe to produce custom cast and machined brass parts. The part was machined with an aggressive cycle time of just 44 seconds per part, and machining ran unattended overnight to maximize production efficiency.

However, one night, the robotic arm misaligned a part during loading, damaging the fixture. The error went undetected, and over 400 defective parts were machined before the team returned the next morning-resulting in substantial material waste, fixture replacement, and costly downtime. For a high-speed operation machining forged brass, even one night of unmonitored failure had major financial consequences.

The one missing piece in its automated process was the ability to monitor and control the cutting process and automation in real time-ensuring errors like this could be caught and corrected before escalating.

To mitigate the risk of unmonitored errors in their automated cell, the customer purchased Caron Engineering's TMAC system. This solution integrates power sensors to continuously monitor the spindle's real-time cutting power, allowing it to learn the cutting process and precisely detect tool wear and breakage.

TMAC learns the optimal power for each toolpath-establishing upper and lower power thresholds based on the learned optimum power for each tool and cutting section. If cutting power deviates from these limits, TMAC reacts instantly, stopping the machine within 5 milliseconds of an extreme alarm to prevent damage to the tool, part, and fixture. Based on learned limits, TMAC will register an alarm if any condition deviates beyond the acceptable cutting parameters and stop the process.

Now if the robot loads the part incorrectly, TMAC will stop the process before any damage can occur. This protection eliminates the risk of mass scrap and costly downtime, allowing the customer to confidently run 24/7 unattended production with consistent part quality and process control.

"In a fully automated, lights-out environment, TMAC plays a critical role beyond just protecting equipment," said a company spokesperson. "In addition to safeguarding the machine and monitoring tool wear and breakage in real time, TMAC helps ensure that all cutting conditions are properly met. Without TMAC, there is no system verifying that every feature is machined to specification-or stopping the process when they are not. By actively monitoring each cut, TMAC enables improved part quality and process control-especially when no operator is present."

Beyond these capabilities, TMAC captures rich data from the cutting process, enabling manufacturers to better understand tool performance, refine cutting programs, and optimize production over time.

Customer benefits include:

- Eliminated large-scale scrap: Catches the first failure event to prevent hundreds of defective parts

- Validated cutting conditions: Ensures all machining operations stay within defined tolerances

- Minimized downtime: Reacts in milliseconds to avoid extended fixture or spindle damage

- Increased automation confidence: Enables reliable, lights-out machining with built-in process oversight.

For more information contact:

Caron Engineering, Inc.

116 Willie Hill Rd.

Wells, ME 04090

207-646-6071

marketing@caroneng.com

www.caroneng.com